Hydraulic System Failure: Common Causes and How to Avoid It

Complex as they are, hydraulic systems across applications share a few key components – and vulnerabilities. Whenever a hydraulic system fails, operators quickly identify and resolve the issue but may not have the time and resources to investigate underlying factors contributing to the outcome.

Take a quick refresher course on a basic hydraulic system and the most likely causes of failure in key applications.

Back to Basics: Hydraulic Systems 101

Hydraulic theory is based on the premise that the application of pressure on an enclosed liquid is transmitted undiminished. It’s a core tenant of Pascal’s law and includes two important additional points:

- Pressure can be exerted from any direction upon a liquid.

- Force is expressed in any and all directions from the liquid to the container walls.

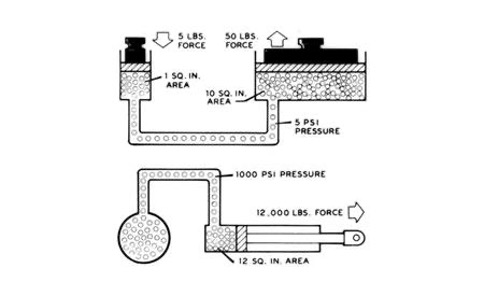

The result is an amplifying effect; five pounds of force (expressed as pounds per square inch) on a 1-inch square area creates 5psi internal pressure.

The application of hydraulic systems in daily life relies on this amplifying force to meet the needs of countless machines, from dishwashers to forklifts and office chairs to construction equipment.

A quick look at the diagram of a hydraulic system shows how central hydraulic fluid is to proper function and the system’s overall integrity.

What Are the Most Common Causes of Hydraulic System Failure?

In most cases, hydraulic systems fail due to improper or inconsistent maintenance, despite the best efforts of facility management and machine operators. The application of hydraulic systems in industry and heavy-duty manufacturing creates persistent high-stress environments – and everyone has a deadline to meet.

When hydraulic systems fail, these are the three usual suspects.

1. Hydraulic Fluid Contamination

Air, water and chemical contamination contribute to between 80 and 90% of all failures, partially because it’s often a secondary consequence of the additional issues noted below.

Air contamination occurs in two ways:

- Cavitation – Often diagnosed by a whining sound while in use, cavitation is caused by dissolved air. Most hydraulic oils have a small amount of dissolved air (usually 9% or less by volume). In certain systems, the hydraulic pump can pressurize and remove dissolved air, resulting in pressure loss and damage.

- Aeration: Aeration occurs when air enters the pump from an outside source, usually from a broken seal.

Water contamination is usually caused by similar system leaks and condensation from extreme temperature changes.

2. Functional Temperature Problems

Temperature from system operations contributes to system degradation more often than environmental factors. Systems operating in extreme heat or cold can cause chemical changes to fluid compounds, altering their molecular and performance characteristics. For example, for every 10 degrees above normal operating temperatures, the life of the fluid is cut in half. The result is one or more changes in fluid viscosity, namely, fluid thinning and fluid thickening. Both can negatively impact performance.

3. Fluid Levels, Leaks and Seals

Most industrial hydraulic systems require hyper-specific fluid volumes to function properly. Leaks or bad connections usually cause low fluid levels, often resulting from worn, broken or improperly fitted seals. Over time, too little hydraulic fluid increases the risk of premature wear or inconsistent performance caused by low pressure.

High fluid levels also pose problems. Too much fluid amplifies force beyond the system’s threshold and can cause complete system failure and pose a risk to operators in the event of an explosion. High fluid levels are usually the result of improper maintenance or rushed

Some of the most common types of industrial hydraulic fluids include:

- Petroleum-based hydraulic fluids – Known for rust protection and superior performance, petroleum formulations are highly flammable, which poses a safety risk for operators.

- Water-based hydraulic fluids – Low-cost, fire-resistant and combines well in various formulations.

- Synthetic blend hydraulic fluids – Ideal for high-temperature environments and a fire-resistant alternative to petroleum products.

- Biodegradable hydraulic fluids – Made with soybean, rapeseed or sunflower oil, these are an eco-friendly alternative that pose substantially less risk to machine operators.

The Top Hydraulic Fluids for Automotive Applications

Tilley Distribution recommends Mobil™ hydraulic fluids for commercial automotive and agricultural applications, including:

Heavy-Duty Tractor Hydraulic Fluid

Heavy-Duty Mobil Hydraulic Systems

- Mobil DTE 10 Excel™ Series

- Mobil DTE™ 20 Series

- Mobil SHC™ 500 Series

- Mobil SHC™ Hydraulic EAL

- Mobil EAL 224H

Our team can also support ongoing maintenance with in-depth fluid analysis. Tilley Distribution’s Mobil Serv Lubricant Analysis can reduce hydraulic failures and help keep your operations running smoothly.

Get More Out of Your Hydraulic Systems with Tilley Distribution

We’re committed to supporting our clients’ growth. For more than sixty years, we’ve invested in a robust distribution network and strong relationships with leading hydraulic fluid and system manufacturers. See what our experience and capabilities can do for your business. Speak with a Tilley representative today.